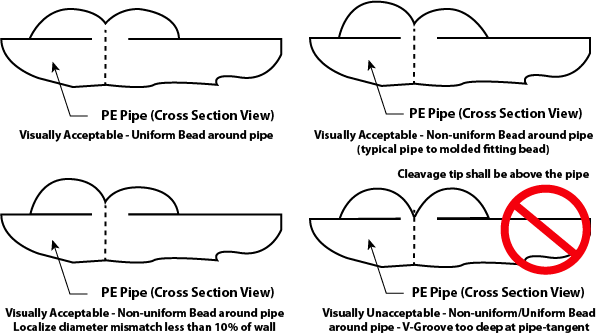

Acceptable & Unacceptable Bead Cross-Sections

The v-groove between the beads should not be deeper than half the bead height above the pipe surface. When butt fusing to molded fittings, the fitting-side bead may display shape irregularities such as minor indentations, deflections and non-uniform bead rollover from molded part cooling and knit lines. In such cases, visual evaluation is based mainly on the size and shape of the pipe-side bead. (See figure below for bead configuration). Visually unacceptable joints should be cut out and re-fused using the correct procedure. (See manufacturer's visual inspection guidelines.) A data-logging device can be attached to the hydraulic fusion machines to record the critical areas of the butt fusion process. This data can be reviewed before allowing the joint to be buried to make sure the proper fusion procedure was followed by the operator. This information can be downloaded to a PC as a permanent record of the joints on a job. The datalogging of each joint on a job can be specified as a QA requirement.