Facing/Alignment

Facing

The pipe ends must be faced to establish clean, parallel mating surfaces. Most equipment manufacturers have incorporated a rotating planer block in their facers to accomplish this goal. Install the facer in the fusion machine and move the pipe ends against the facer. Facing is continued until a minimal distance exists between the fixed and movable jaws of the machine and the facer is locked firmly and squarely between the jaw bushings. Open the jaws and remove the facer. Remove any pipe chips from the facing operation and any foreign matter with a clean, lint-free cotton cloth. Bring the pipe ends together with minimal force and inspect the face off. A visual inspection of this operation should verify that faces are square, perpendicular to the pipe centerline on each pipe end and with no detectable gap.

Ref: Polyethylene Piping Systems Field Manual for Municipal Water (Irving, TX: The Plastics Pipe Institute, 2010)

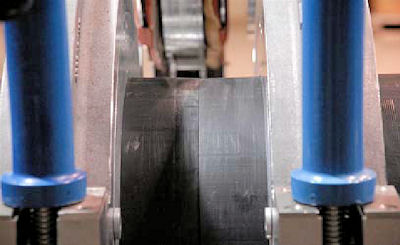

Alignment

The pipe profiles must be rounded and aligned with each other to

minimize mismatch (high-low) of the pipe walls. This can be accomplished

by tightening clamping jaws until the outside diameters of the pipe

ends match. Always tighten the high side down to achieve alignment. The

jaws must not be loosened or the pipe may slip during fusion. Re-face

the pipe ends if excessive adjustment is required and remove any chips

from re-facing operation with a clean, lint-free cotton cloth.

Ref: Polyethylene Piping Systems Field Manual for Municipal Water (Irving, TX: The Plastics Pipe Institute, 2010)