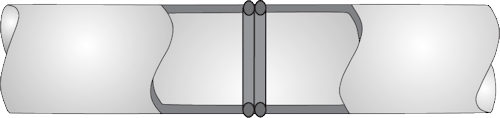

Butt Fusion

Standard Butt Fusion Joint

The most widely used method for joining individual lengths of PE pipe and pipe to PE fittings is by heat fusion of the pipe butt ends (butt fusion). This technique produces a permanent, economical and flow-efficient connection. PPI Technical Report TR-33, Generic Butt Fusion Joining Procedure for Field Joining of Polyethylene Pipe and ASTM International F 2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings and ASTM International F 2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings, provide recommended practices for the generic butt fusion joining procedure.

In some pipe systems, engineers may elect to remove the inner or outer bead of the joint, using appropriate tools and procedures. Since the fusion must be completely cooled before bead removal, assembly time is increased slightly. However, it is uncommon to remove internal beads, as they have little or no effect on flow, and removal is more time-consuming, requiring use of a cutter fitted to a long pole following each fusion.

PE pipes of the same outside diameter but having different specified wall thicknesses (i.e., different DR designations) may be butt fused to each other under special conditions, but is subject to limitations, requiring consultation with the pipe manufacturer.

Standard Butt Fusion Joint